Can you do this with your arc weld process? No Arc length Volt Control - No Weld Gap - No Edge Prep - No Spatter - No Distortion - No Weld Rework - No Stainless Carcinogenic Weld Fumes.

Hot Wire GTAW & Automated TIP TIG Weld Applications

Since 2009 in N.America, no other automated arc weld process has enabled the weld quality and part mechanical or corrosion properties capability of TIP TIG.

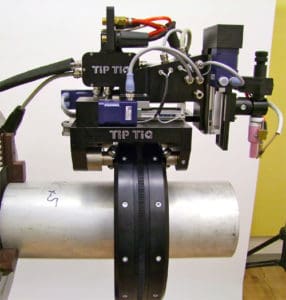

Above, single-pass, one side automated TIP TIG full penetration, 4 mm, 300 series stainless. On this application TIP TIG used to provide a single pass, keyhole (full penetration) weld without a gap or edge preparation. Approx 450 amps is used with a weld travel rate of approx 35 inches/min.

After being used on your manual welds in the shop, just attach the TIP TIG torch to a mechanized carriage or rotating positioner, this process is not arc length sensitive like DC TIG and Hot Wire TIG.

ONE PROCESS. Use TIP TIG from any root to fill passes and remember in your weld shop, this will be the only weld process capable of consistently producing manual or automated defect free arc welds.

It’s a pity it took SpaceX approx. a decade to figure out that to produce manual stainless tank welds that had the best chance of consistently passing any destructive pressure / cryogenic test, you select the TIP TIG process.

With the semi-automated TIP TIG unit you can as shown with the above stainless tank, attach a low cost mechanized carriage unit and drom root to fill attain best possible automated welds. Note the unusual color (lack of oxidation on the multi pass stainless welds.

Most TIP TIG automated welds will be made between 100 to 350 amps with weld speeds similar to pulsed MIG welds. If you don’t want to do automated keyhole welds, its easy to do open root automated welds and I would recommend welders also start to consider using a pulsed mode on open TIP TIG roots.

NO PURGE – NO GOUGING – NO ROOT REWORK. As for a unique manual approach to large fabrications that require an open root, you may want to take a look at the above right video, here we have two manual TIP TIG welders (one either side) using a unique root technique that will require no gas purge or back gouging and ensure no root weld rework.

It’s no good me talking about the new welding methods enabled by TIP TIG, without providing you with some of the weld quality and cost benefits attained.

- Note the TIP TIG weld speeds attained with the keyhole root weld.

- Note the weld quality being attained without costly edge prep or concern.

- Note the TIP TIG lack of stainless Hex Chrome weld fumes.

- Note no spatter, and no cleaning or grinding required.

- With manual or automated, weld shops should appreciate the lack of distortion and stress concerns with improved mechanical – corrosion properties.

- TIP TIG, one weld process delivering the unique attributes of the highest energy welds with the lowest welded part heat input.

- TIP TIG, one weld process, one set of best weld practices, one weld wire, one gas, one weld procedure.

TIP TIG enables progressive cost effective weld changes, that however will require someone to lead, implement, train and own. TIP TIG training resource on automated / manual welds, available at the bottom of the page.

TWO WELDER APPROACH TO OPEN ROOTS: The two-manual TIP TIG welders open root and fill pass approach can be the first step in applying the root pass and then utilizing the same weld equipment and a torch beneficial on large steel, or alloy steel Vessels, LNG Tanks, or for example, on the SpaceX Starship. With the two-pass root with one TIP TIG welder on one side, the other on the opposite side with the ID torch trailing about 25 – 50 mm behind. This “two-sided root and blend” method is challenging to do with DC TIG due to the slow weld speeds, but easy to do with the higher weld speeds from TIP TIG.

Be also aware of the dramatic weld cost savings from the required TIP TIG Vee edge prep total that could be 45 to 50 degrees. Of course, extensive weld cost savings also come from the ability to produce the first time, defect-free root welds ready for the TIP TIG fill passes, which should not require weld rework.

BEFORE CONSIDERING THE AUTOMATION CONSIDER THE WELD PROCESS

TIP TIG has equipment for any automated weld appliction, however weld shops must also be aware that with automated or manual welds, pulsed MIG, GTAW and also Hot Wire TIG, are not capable of the weld quality and welded part properties. So before the weld shops would purchase costly weld automation examine the weld process and its capability FIRST. As TIP TIG is a semi-automated weld process it will also attain a weld quality many weld shops are getting with present weld automation and existing arc weld processes.

With the best weld process, low cost automation may be all you need

Don’t try to duplicate this weld with your TIG, Pulsed MIG or flux core weld process you would be wasting time.

Often the best and most economical welds will come from low cost automation such as a carriage or rotary turntable, and that quality will be at a max when TIP TIG is used.

As you note, all these 6 mm stainless fillet weld needs are a steady hand. Note the weld surface fluidity, yet a weld color that denotes minimal oxidation influence.

- Approx 28 inch / min.

- No weave required.

- No spatter to clean.

- No concern for flange distortion.

- No concern for weld stresses.

- No concern for carbide precipitation.

- No concern for cleaning or grinding.

- No concern for chrome weld fumes or dust.

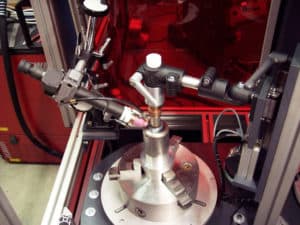

HOT WIRE.. The most common automated GTA weld process for pipe or bore ID or OD has been the Hot Wire GTA Process, a process that does not have the weld capability of the TIP TIG process.

Many companies will make Hot Wire pipe welds or ID – OD clad welds; however, the Hot Wire process will often require arc length sensing equipment. On many welds It may provide lower deposition, especially with low to moderate amp applications. These companies are often not aware that TIP TIG:

- Rarely requires costly arc length sensing equipment.

- Will provide better weld fusion and lower weld porosity.

- Will often allow larger wire diameters with increased weld deposition rate potential.

- Will enable the lowest weld fume potential.

- It is also a manual process.

Manual or automated welds, remember that the building blocks of any automated or manual welds are the ease of welding, the all position capability, the weld energy and fluidity generated and the weld purity attained

When it came to arc welding, in 2009, China went ahead of the N. American & European Sub Sea Industry.

Notice the above clad weld uniformity and continuity after 4 Inconel weld layers were made without stopping and without time consuming inter weld pass temperature controls. This capability simply points at the feature of TIP TIG to enable highest weld energy with lowest weld heat input.

The young man above who struggles daily in China to make a living was never aware that daily he was producing a pipe Inconel weld and clad quality and productivity that had never been produced by any engineer anywhere else in the world.

After the first TIP TIG workshop that I presented in 2009 at our Philadelphia facility, the Chinese CNOOC engineers that attended stayed over for a week, and Tom and I welded 12 hours a day proving the automated and manual TIP TIG weld and clad capability at our TIP TIG facility.

My business partner Tom and I first proved the TIP TIG capability with the Inconel 5G manual welds, and followed with the automated inconel clad requirements. All weld tests first time consistently passed with flying colors.

Part of the sub sea pipe application also required the Inconel clad pipe ends be manual welded in the 5G position. Left you see two CNOOC TIP TIG welders producing defect free pipe welds faster than has ever been possible with TIG – Pulsed MIG and Flux Cored. Where are the Hex loaded fumes? you might ask. As the Sub sea pipe welds were made in the confined area of the ships, all involved appreciated a process that also produces the lowest possible welds fumes.

Part of the sub sea pipe application also required the Inconel clad pipe ends be manual welded in the 5G position. Left you see two CNOOC TIP TIG welders producing defect free pipe welds faster than has ever been possible with TIG – Pulsed MIG and Flux Cored. Where are the Hex loaded fumes? you might ask. As the Sub sea pipe welds were made in the confined area of the ships, all involved appreciated a process that also produces the lowest possible welds fumes.

CNOOC welding Sub sea Pipe

TIP TIG. One process for 5G manual root to cap and same process for 5 G automated clad. Two simple settings for all the welds. One wire. One gas. No weld spatter. No weld cleaning. No weld inter pass controls. No weld rework. Sub sea – companies or anyone that welds pipe or produces clad welds in Europe and N. America, remember that Bob Dylan line “the times they are a changing”, and if you don’t remember that. for gods sake try at least in your weld shops to keep up with China.

The largest Subsea oil company in China had a weld issue no one could solve. Then they came to my workshop on TIP TIG

More info on New Sub Sea Weld Practices.

So when CNOOC , the largest offshore oil company in China, needed to improve weld quality and productivity, it was determined that a new arc weld approach was required to lay many miles of Subsea Pipe. The 5G position cladding and pipe weld joining was produced offshore on costly pipe-laying ships. The pipe ends had 5G automated clad welds in which with 3 to 4 layers of Inconel was applied. Then the 5G pipe ends were manually welded together again using Inconel filler.

CNNOC wanted to do the automated clad and manual Inconel pipe welds faster than anyone else in this industry. Also, they required all the welds first time pass X-rays with zero weld defects. To add to this weld challenge, no inter-pass temp was allowed for the multi-layer clad welds.

For those of you that have ever applied four layers of Inconel on the ID pipe ends. This is a weld location in which the weld heat buildup has nowhere to go except remain in the pipe end and welds. To control the required weld dilution and the Inconel clad weld solidification would typically be made with 20 th Century weld practices such as weld inter-pass temp, controls which was not allowed.

To attain their unique Sub sea weld quality and productivity requirements, at first CNOOC engineers approached two of the world’s leading MIG, and TIG weld equipment manufacturers, Fronius for MIG and Liburdi for TIG, and their best engineers and weld equipment failed to meet their weld demands.

Around 2009, CNOOC sent a group of engineers to one of the first TIP TIG Seminars that I provided at our facility at the Philadelphia Naval Yard. This was the same workshop attended by SpaceX personnel, who unfortunately took another ten years to figure out the weld benefits of TIP TIG.

Is it a sign of the times, that it took me in 2008, approx, 10 minutes to figure out that TIP TIG process provides numerous weld benefits and belongs in N America. With the Chinese CNOOC engineers, it took about a hundred working hours for the engineers to figure out this is the process they need and TIP TIG belongs in China and SpaceX took 10 years.

China adopts Advanced European Weld Technology while N. America appears to be stuck in the 20th Century.

Is it me, or is it a reflection of where we are in 2020 in N America that most of the weld decision makes in oil – gas – defense – aerospace, power, and medical industry are still welding the way it was done way back in the 20th Century.

A semi-automated TIP TIG weld and a rotating part will also provide the weld shop with a weld quality and the lowest weld heat input that for 70 years has not been possible with TIG - MIG - Flux Cored. TIP TIG is not creating the following weld fumes, the contaminates on the following shaft or blade are responsible for the fumes.

When welding Stainless, weld shops are aware of the weld fume Hex Chrome Carcinogenic concerns, It is inexcusable when weld shops as this one did, leave lubricants or cleaning solvents on their stainless parts.

One Weld Process. One Weld Procedure. One Weld Wire. One Weld Gas. No Distortion. No Weld Rework.

- With manual welds, no arc length sensitivity concerns. With most automated welds, no costly Arc Length Control.

- Note welds speed similar to MIG. Weld automation would enable higher weld speeds,

- Use one process from root to fill for all code automated / manual welds.

- Always highest weld quality.

- Always lowest welded part distortion,

- Consistently highest mechanical and corrosion properties,

- And WITH CLEAN PARTS, no weld fumes generated.

Note the weld color which is an indication of lack of oxidation. Producing optimum weld quality while reducing oxidation potential not only means less weld porosity potential, it also means less weld brushing and less weld grinding which reduces the concerns for stainless dust particles in the welding or manufacturing area. On an application like this also think of the TIP TIG benefit attained from enabling the lowest weld distortion,

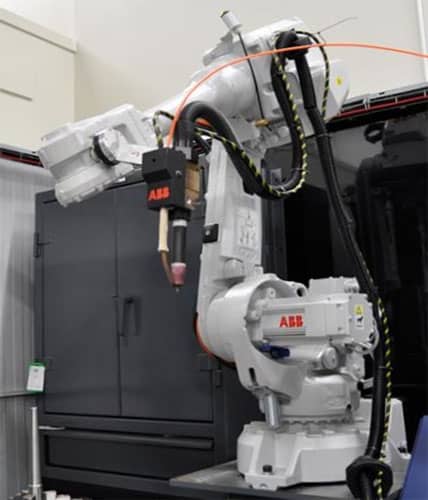

For Decades TIG was poorly suited for Robot welds and MIG provided many weld concerns

FOR DECADES TIG WAS POORLY SUITED TO ROBOT WELD APPLICATIONS DUE TO THE ARC LENGTH SENSITIVITY AND THE POOR WELD DEPOSITION RATES PRODUCING SLOW WELD TRAVEL RATES.

I used to be the North American Weld Manager for ABB Robots and was responsible to evaluate all robot applications for weld feasibility and risk.

When companies in industries such as Aerospace – Defense – Oil – Power wanted to use TIG welds with robots, at ABB I would bring up the weld risks that would influence robot down time. With the DC TIG welds there would be concerns that were influenced by the “arc length sensitivity”. There would be concern about the erratic tungsten wear that was also greatly influenced by the arc length. I would have to explain to the customers that rarely would the robots allow for more TIG weld production as a result of the restricted robot weld speeds influenced by the poor weld deposition rates and unplanned downtime.

Approx. 5 years after I left ABB and started TIP TIG USA, I went back to the US. ABB Robot Weld facility around 2010. I provided a TIP TIG work shop to all the Robot Weld Engineers and managers, showing them the unique robot weld quality, weld productivity and welded part metallurgical benefits that they could now present to the aerospace, defense, power and oil companies. As is a common theme on this site, it also took the ABB weld decision makers at the one of the world’s highly respected engineering companies, another 10 years to finally come to the conclusion that should have taken a good weld engineer 10 minutes. Finally around 2009 ABB mangers and engineers woke up and selected the TIP TIG process as their arc weld process of choice best suited when their customers wanted the best possible weld quality or the best possible weld metallurgy.

Lack of weld process knowledge consequences cost defense, aerospace, oil and power industries, millions of dollars a day.

The army could have had their titanium howitzers manually and robot welded with TIP TIG without gas purge and without oxidation concerns way back in 2009, and saved themselves hundreds of millions of dollars.

So for those engineers and managers in the high tech industries, please take a moment and think about the possibilities by placing the world’s best arc weld process on a robot.

- The robot and TIP TIG combination will enable those companies using DC TIG to typically attain a 300 to 500% increase in hourly weld production.

- In contrast to all other arc weld processes, the robot and TIP TIG could provide, the most consistent and the highest possible uniform weld quality.

- While manual TIP TIG in contrast to DC TIG and Pulsed MIG already produces the lowest possible welded part heat input, typically around a 35 to 50% joules reduction. That joules reduction is further reduced by the increased robot weld speed potential enabling enabling weld and part metallurgical properties never before possible. Also this enables the lowest possible distortion.

No spatter, no weld cleaning and no exhaust equipment required. All it takes is managers and engineers to have an open mind view, the weld process and then make A RATIONAL, COST EFFECTIVE, ENGINEERED DRIVEN WELD PROCESS SELECTION.

According to this Lincoln add. on Linked. “Welding shortages are making it harder than ever for manufacturers to find the skilled labor they need. And when it comes to the highly specialized TIG process, finding top talent that can deliver on quality can be an even greater challenge.

Here is the 2020 weld reality. First Lincoln ignores the 12 year old TIP TIG process when it states about skilled welder shortages as TIP TIG is easy to learn and within 10 days, any none welder could learn manual TIP TIG and meet any all position code welder qualification requirements. Also and keep this in mind when you are considering the costly purchase of any robot GTA units that will use filler metals. The weld reality is a MANUAL TIP TIG welder will likely provide higher weld quality and greater hourly weld productivity than most robot GTA welds made with with filler metals, unless that robot is using TIP TIG. I am aware talk is cheap, but I would travel to any plant, and prove my points and it will only take a day.